The Flexo Wash Laser Anilox Cleaner is the headliner of leading cleaning technology. Safe, effective and environmentally friendly, this cleaner is proven to efficiently and thoroughly clean your anilox rolls.

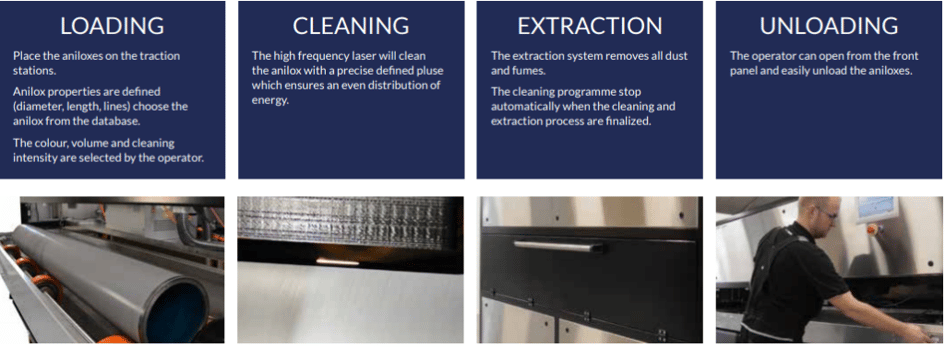

How does the laser work?

The laser beam works on the principle of the ablation: the ink or coating on the anilox surface is evaporated due to the temperature generated by the laser energy. Since the ink basically becomes ash, this solution is the most sustainable cleaning method. The vapors are absorbed by the air vacuum filter. When using a laser cleaner, no chemicals or water are needed or required, thus making it extremely environmentally friendly compared to the other options.

But, as with any new technology, people have many questions about the safety of the laser cleaner.

We are here today to clear up any misgivings and answer our most asked questions about the Laser Cleaner.

Frequently asked questions about the Laser Cleaner:

1. Does the laser in any way alter the anilox cell?

NO. The laser thoroughly cleans the anilox cell without altering it. The laser is calibrated to safely clean the anilox cells without damaging them. In fact, the cleaning of the anilox cell actually reinvigorates the cell volume, returning it to good condition.

2. Does the laser damage the surface of the anilox?

No. Because the laser works through the process of ablation, the inks and coatings on the surface of the anilox disintegrate, leaving a clean anilox behind. The laser is actually a much safer and effective method of cleaning than many others.

3. How is this laser cleaner different?

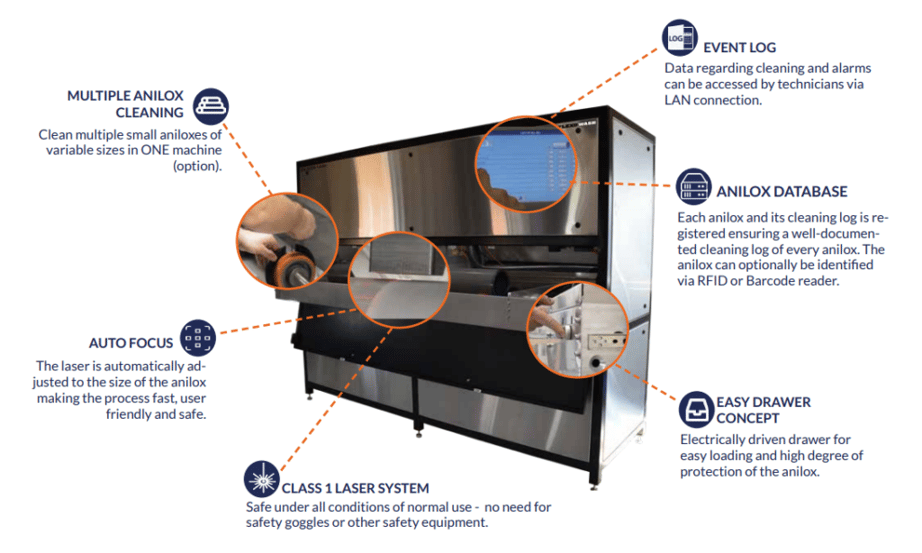

This laser cleaner is developed with cutting-edge technology and software systems. It uses auto-focus to automatically adjust to the size of the anilox roll, making the process fast, user-friendly and safe.

4. Laser cleaners are expensive, right?

Actually no. These laser cleaners can actually clean multiple aniloxes of variable sizes at the same time in this one machine. That aspect alone saves money, without many unnecessary single cleanings. Also factor in that there is no ongoing consumables or waste. Lastly, since this system is fully-automatic, there is no labor involved with cleaning.

5. Is it safe for operators to be around a laser?

Flexo Wash’s Laser Cleaner uses a Class 4 Laser System, but because it is contained within the enclosure of the machine, it is considered a Class 1 laser. A Class 1 Laser is safe under all conditions of normal use. There is no need for safety goggles or other safety equipment.

6. Are lasers hard to use?

Laser cleaners are fully-automatic, requiring very little labor. The laser has auto focus, and automatically adjusts to the size of the anilox, making the process fast, user-friendly and safe. The easy drawer concept allows for simple front loading of the anilox into the machine, while also protecting the anilox. The Flexo Wash Laser Cleaner has an anilox database, which registers each anilox and tracks its cleaning and condition on a documented log. This takes the guesswork out of cleaning your inventory.

7. Aren’t lasers actually BAD for the environment?

Because the laser has no ongoing consumables or waste, it is a sustainable cleaning method. It uses very little energy and has a small footprint: in fact, a basic household appliance uses more energy than a laser cleaner.

8. What about the remaining ink particles, can they be harmful to the user?

No, Flexo Wash’s Laser Cleaner vacuum uses three stage air filtration. The remaining ink particles and other micro-particulates first go through a fiber filter and any smaller particles are then captured in a two-stage HEPA filter eliminating all of the ash and any additional micro-particulates.

Feel free to contact us anytime for all your questions and concerns.

www.flexowashus.com

1-888-493-5396